U-value ETFE cushion, the rout to precise determination 2025.

- Fabrix360

- Apr 1, 2020

- 3 min read

Updated: Aug 6

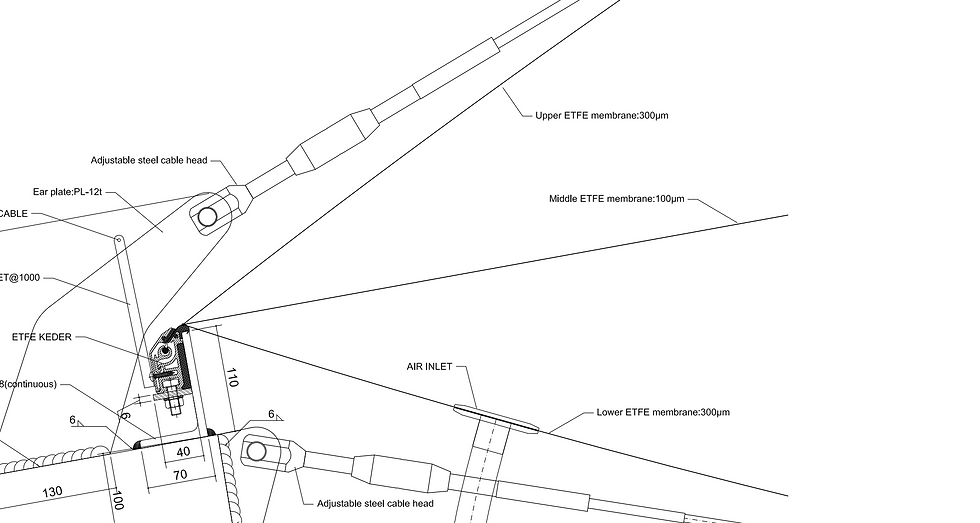

Conventional calculated U-values which are agreed among most main etfe fabricators and designers are approximately 2.6 W/m2.K and 1.8 W/m2.K for double layers and triple layers respectively(based on existing now adays standard applications). The U value here is for etfe part only usually referred to as Ug (glazing) , means it does not include the framing or its not Uw (window). However, the standards being used in calculations are best fit with conventional constant cavities of walls or roofs, even the laboratory testing rigs are best fit with those conventional constant cavities and opaque/hard materials. This is fundamentally different than etfe cushion in two main aspects, first one etfe cushion has no constant cavity(the cushion is very thick in the middle and goes to zero at aluminum extrusion, second the etfe is super translucent or transparent materials.

Architectural ETFE (Ethylene Tetrafluoroethylene) is a highly durable, lightweight, and transparent fluoropolymer material used in building envelopes, offering exceptional strength, UV resistance, thermal performance, and design flexibility for innovative and sustainable architectural applications.

Taking the above into consideration, we can state the following rout for better understanding of etfe cushion U value.

1- In ETFE cushion the thermodynamics of heat transfer(heat flux) is resisted basically by three main barriers which are the materials of etfe film being used, the number of air cavities(one in double layers, two in triple layers, and the thickness of the air cavity or air cavities-if more than double layers- ).

2- The conventional thermal calculations typically involves five decimals coefficients and some exponential figures, therefore it is believed that calculations alone may provide us approximate results in etfe cushion case due to the reasons aforementioned. Yet, one must state that for preliminary evaluation that can be acceptable.

3- Because there are no identical set up for etfe cushion projects(every project has its own materials specifications, number of layers and thickness of air cavities) and In order to precisely quantify the thermal performance via U-value, a specific test and testing rig must be involved to experimentally determine the U-value for each cushion set up taking into consideration the actual proposed system of cushion as designed including the framing proposed. such U value then must be shared with HVAC engineer and make sure it is being considered in the project to meet the targeted thermal comfort/performance.

Finally, it may sound overwhelming and expensive to undertake such testing, but that can be mitigated after several set ups actual testing you may start repeating them, in addition to that such testing gives the etfe designer an important information about differences between calculated models and actual testing ones which will enable her or him eventually to adjust the existing standard methods of calculations to suite ETFE, not to mention that in important projects or mega projects any misinformation in such crucial information may lead to massive amount of recovery costs in HVAC load nd/or the roof itself, that alone believed enough reason to implement the actual testing until some point and time we get enough information on etfe cushion heat transfer behavior like what we do have now in conventional materials.

For practice on ETFE facades determination of U_value visit our web application design tools by clicking on below button and register for free and try/estimate U value by yourself:

Hope you find this post interesting. fabrix360 is your trusted ETFE and glass expert, do not hesitate to contact us for any query.

Comments